Fertilizers play a crucial role in agriculture where they are used to provide the necessary nutrients plants and crops need to grow exceptionally and provide exponential yields. However, everything changed back in the 19th Century when the so-called Green Revolution brought new innovations transforming the global food system and allowing for larger-scale industrial agriculture.

This is where fertilizer pumps were able to deliver tremendous efficacies to provide nutrition for farmlands and helped in amplifying the production capacity of agricultural landscapes. In fact, the use of nitrogen fertilizers, in particular, led to an 800% increase between 1961 to 2019. Let’s take a closer look at what are fertilizer pumps.

What is a Fertilizer Pump?

As the name implies, fertilizer pumps are fully functional machines that are specifically designed for the purpose of transferring fertilizer to your supply and nurse tanks. These pumps can then help in the fertigation process which is the process of injecting fertilizers. This applied fertilizer then amends the soil and makes it more habitable for plants and crops to grow.

How do Fertilizer Pumps work?

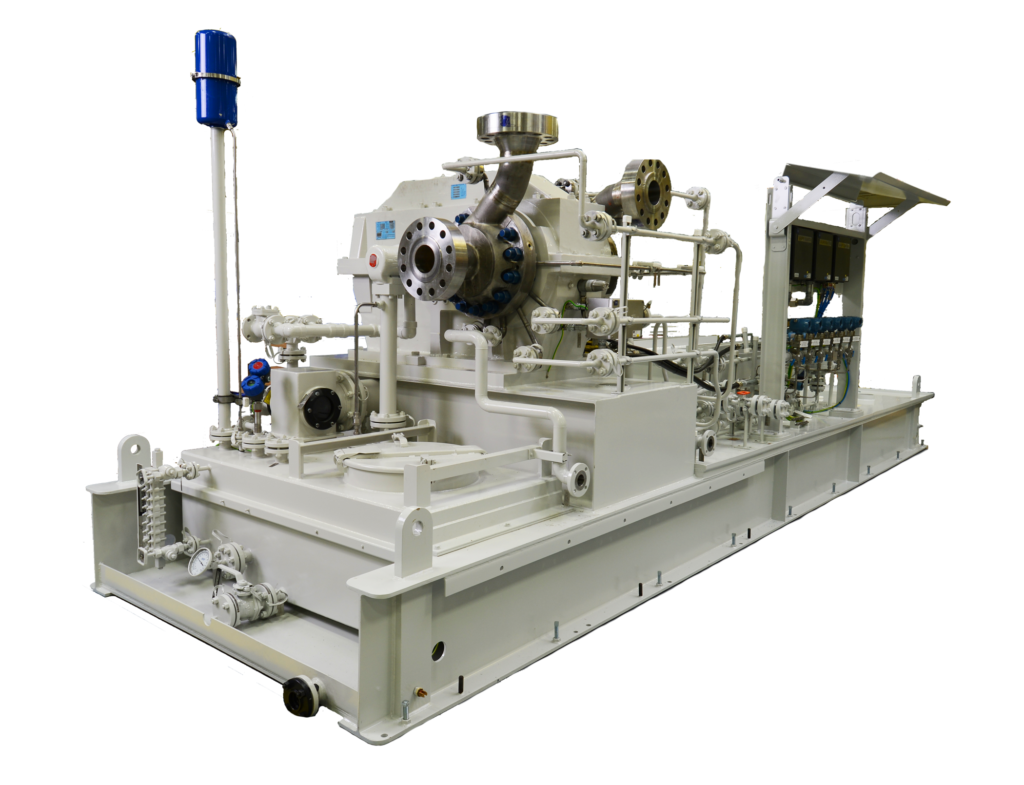

The majority of fertilizer pumps are available in variable models including the likes of simplex and duplex. The pumps are engineered in such a way that all exposed parts to chemicals and fertilizers are made from durable and robust material along with deploying the highest quality seals to keep the content within safe and away from harm.

Nowadays you can find several types of fertilizer pumps such as centrifugal pumps, diaphragm pumps, injection pumps, and piston pumps to name a few. While every single one of them has its own particular functionalities they each apply pressure in some way to mix water with the required percentage of fertilizer concentrate. The resulting mixture is then passed onwards to where it needs to be applied.

Benefits of Using Fertilizer Pumps

It goes without saying that by using fertilizer pumps the application becomes quite convenient and hassle-free. For larger-scale production, fertilizer pumps are absolutely essential as they are able to impart economies of scale as well as require less manpower assistance to get the job done in a quicker and faster manner.

Efficient fertilizer pumps with excellent capabilities and features can make the process much easier and also ensures a wider application with better outcomes for agricultural sites and farmlands. Research and studies regarding the usage of fertilizer pumps have shown that by providing the right amount of fertilization to your crops, farmers can triple the size of their harvest.

Common Types of Fertilizer Pumps

As mentioned earlier that there is an assortment of fertilizer pumps available for large-scale industrial agricultural use, however, there are two amongst them that deliver outstanding advantages. They are the Centrifugal and Plunger Pumps. Here is a quick breakdown for them both:

Centrifugal Pumps

These pumps drive liquids with rotation and the most common form is called a rotary positive displacement pump The liquid in these types of pumps is forced through a rotating basket. When the basket rotates, the liquid flows past the basket into a chamber. The pressure and the shape of the chamber then determine the amount of liquid that can be pumped.

Plunger Pumps

These pumps are identified as reciprocating PD (positive displacement) pumps that can possess one or multiple inline plungers which are configured horizontally. The pump is usually powered by an electric motor or an engine. The plunger section of the pump can be single-acting or double-acting with both suction and discharge stages happening concurrently on the opposed verges of the plunger.

Qualities and Merits of Remarkable Fertilizer Pumps

- The ability to handle abrasive and corrosive materials without bringing anyone harm.

- High-quality seals prevent harmful gases and compounds from leaking into the environment.

- Should be able to create incredibly high suction pressures which can be around 3,000 bar or 43,000 psi.

- The operational efficiencies of fertilizer pumps should be up to 90% or somewhere near that mark.

- It is not uncommon for fertilizer pumps to operate for 20 years if properly maintained through that period.