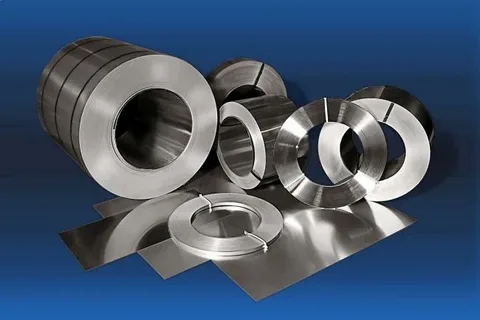

Inconel 625 is a highly popular nickel-chromium alloy with exceptional corrosion resistance and high strength, even in extreme temperatures. As a result, it is widely used in various industries, including aerospace, chemical processing, and marine engineering. If you are in the market for Inconel 625 coils, you may wonder about the factors affecting their price. In this blog post, we will discuss some key factors determining the cost of Inconel 625 coils and how you can make an informed purchasing decision.

Material Costs:

The material cost is one of the biggest factors influencing the price of Inconel 625 coils. Raw materials used for producing Inconel 625 coils come with varying prices in different parts of the world. Besides, the production cost will also depend on the purity of the raw materials used. Inconel 625 coils produced from high-grade materials will cost more than those produced using low-grade raw materials.

Manufacturing Process:

The manufacturing process is another critical factor that affects the price of Inconel 625 coils. The manufacturing process includes several stages, including hot and cold-rolled, annealing, and finishing. The complexity and time taken to produce the coils directly impact the cost—the more intense and time-consuming a manufacturing process, the higher the price.

Manufacturing Location:

The location of production is a crucial factor affecting the price of Inconel 625 coils. Coils manufactured in Northern America and Europe may be more expensive than those produced in other regions, such as Asia, India, or China. Often, the cost of production in these regions is lower and, as a result, impacts the final price of the product.

Types of Inconel 625 Coils

1. Annealed Inconel 625 Coils

Annealed Inconel 625 coils are processed in a controlled atmosphere to achieve their desired mechanical properties. These coils have excellent resistance to corrosion and scaling at high temperatures, making them ideal for use in the aerospace industry. They are also used in the chemical, petrochemical, and marine industries because of their strength, toughness, and weldability. Annealed Inconel 625 coils are available in various sizes and thicknesses and are cost-effective for many applications.

2. Solution Annealed Inconel 625 Coils

The annealed Inconel 625 coils undergo an annealing process followed by water quenching to produce a uniform, fine-grained microstructure. This type of Inconel 625 coil has high strength, resistance to oxidation, and excellent fatigue strength. Solution-annealed Inconel 625 coils are widely used in the oil and gas industry, aerospace, and chemical processing. They are also used in marine applications due to their excellent corrosion resistance.

3. Work-Hardened Inconel 625 Coils

Work-hardened Inconel 625 coils use mechanical deformation to increase their strength and hardness. This coil type has excellent corrosion resistance and is often used in high-temperature applications such as jet engine exhaust systems. Work-hardened Inconel 625 coils are also used in chemical processing plants, nuclear power plants, and offshore oil and gas platforms.

4. Cold-Drawn Inconel 625 Coils

Cold-drawn Inconel 625 coils are produced by drawing Inconel 625 through a series of dies to achieve the desired shape and size. This process results in a coil with excellent tensile strength and fatigue resistance. Cold-drawn Inconel 625 coils are used in applications that require high strength, such as turbine blades, rocket motors, and chemical processing equipment.

5. Precipitation Hardened Inconel 625 Coils

Precipitation-hardened Inconel 625 coils are heated at high temperatures and then rapidly cooled to produce a supersaturated solid solution. This solution is then aged to produce a fine, evenly distributed precipitate throughout the coil. Precipitation-hardened Inconel 625 coils are known for their high strength, toughness, and excellent corrosion resistance. They are used in the aerospace, chemical processing, and marine industries.

Quality & Certification:

The quality of inconel 625 slit coil can significantly impact their price. Coils with higher specifications or certifications, such as AMS 5599 and ASTM 5666, will be more expensive than those without these certifications. The certification indicates that the coils have undergone rigorous testing to ensure quality and performance.

Market Trends:

Market trends also play a role in determining the price of Inconel 625 coils. Supply and demand, geopolitical events, and economic conditions drive the price of Inconel 625 coils. For instance, in times of crisis such as the COVID-19 pandemic, the price of inconel 625 coil and other commodities tends to increase due to a shortage of raw materials or transportation disruption.

Conclusion:

In conclusion, understanding the factors affecting the price of Inconel 625 coils is essential if you want to purchase. Material costs, manufacturing process, location, quality certification, and market trends all play a role in the product’s final price. Therefore, before making any purchase, consider these factors to make an informed decision and buy from a reputable supplier. With this information, you can get the best value for your money and achieve your goals of using Inconel 625 coils.