In the ongoing quest for sustainable maritime practices, the effective management of ballast water has emerged as a paramount concern. Ballast Water Management Systems (BWMS) equipped with sophisticated sensors play a pivotal role in safeguarding marine ecosystems by ensuring the efficient treatment of ballast water. However, the accuracy and reliability of these systems hinge upon meticulous sensor calibration. This article explores the significance of BWMS sensor calibration and its implications for environmental stewardship.In the intricate dance of maritime commerce, the proper management of ballast water stands as a sentinel against ecological upheaval. Central to this endeavor are Ballast Water Management Systems (BWMS), fortified with advanced sensor technologies. However, the efficacy of these systems hinges upon meticulous calibration of their sensors. This article delves deeper into the intricacies of BWMS sensor calibration, revealing its indispensable role in preserving marine ecosystems.

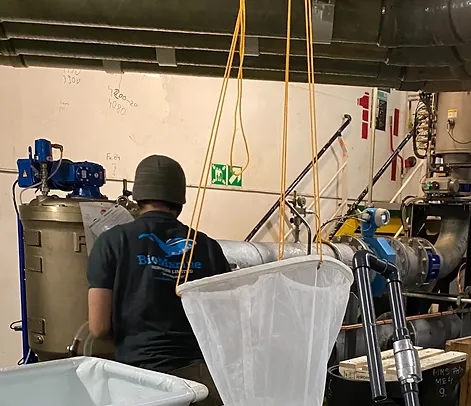

Understanding BWMS and Sensor Technology: Ballast Water Management Systems are designed to neutralize or remove potentially harmful organisms from ballast water before it is discharged into new environments. These systems utilize advanced sensor technology to monitor crucial parameters such as flow rate, temperature, salinity, turbidity, and disinfection efficacy. Sensors provide real-time data that enables operators to assess treatment performance and ensure compliance with regulatory standards.At the heart of BWMS lies the calibration process, a meticulous endeavor that fine-tunes sensor accuracy and reliability. Calibration involves aligning sensor measurements with known reference standards, thereby ensuring precise data acquisition. This process is indispensable for maintaining compliance with stringent regulatory requirements and safeguarding marine ecosystems from the perils of invasive species.

The Importance of Sensor Calibration: Sensor calibration is the process of adjusting and verifying sensor measurements to align with known reference standards. Proper calibration is essential for maintaining the accuracy and reliability of sensor data, thereby enhancing the effectiveness of BWMS in preventing the spread of invasive species and pathogens. Calibration ensures that sensors deliver precise measurements under varying environmental conditions, enabling operators to make informed decisions regarding treatment strategies and discharge protocols.

Navigating Challenges in Sensor Calibration: The journey of sensor calibration is not without its challenges. Environmental variability, sensor degradation, and evolving regulatory frameworks present formidable obstacles. However, proactive measures such as routine maintenance, calibration verification, and operator training serve as beacons of guidance, illuminating the path towards optimal sensor performance.

Best Practices: Pioneering Excellence in Sensor Calibration: To navigate the complexities of sensor calibration with finesse, adhering to best practices is paramount. Regular maintenance routines, encompassing cleaning, inspection, and recalibration, serve as the foundation of sensor reliability. Calibration verification, through the judicious use of reference standards and secondary methods, instills confidence in measurement accuracy. Harnessing the power of data analysis enables operators to glean insights, optimize treatment processes, and chart a course towards environmental sustainability. Lastly, investing in comprehensive operator training cultivates a culture of proficiency, empowering individuals to navigate the intricacies of sensor calibration with confidence and competence.

Challenges in BWMS Sensor Calibration: Calibrating sensors in BWMS presents unique challenges, including:

- Environmental Variability: Ballast water conditions can fluctuate significantly based on factors such as location, water source, and vessel activity, necessitating adaptive calibration strategies.

- Sensor Degradation: Sensors may experience drift, fouling, or mechanical wear over time, leading to inaccuracies in measurement and potential non-compliance with regulatory requirements.

- Regulatory Compliance: Regulatory bodies such as the International Maritime Organization (IMO) and the U.S. Coast Guard (USCG) impose strict standards for ballast water treatment and discharge, mandating accurate sensor calibration to demonstrate compliance.

Best Practices for BWMS Sensor Calibration: To address these challenges and optimize the performance of BWMS, the following best practices for sensor calibration should be observed:

- Routine Maintenance: Implement a regular maintenance schedule to clean, inspect, and recalibrate sensors to mitigate drift and ensure accuracy.

- Calibration Verification: Periodically verify sensor calibration using certified reference standards or secondary calibration methods to validate measurement accuracy.

- Data Analysis: Utilize historical sensor data to identify trends, diagnose calibration issues, and optimize treatment processes for enhanced efficiency and compliance.

- Operator Training: Provide comprehensive training to operators on sensor calibration procedures, troubleshooting techniques, and regulatory requirements to promote consistent and effective calibration practices.

Conclusion: As the maritime industry continues to prioritize environmental sustainability, the proper calibration of BWMS sensors emerges as a critical factor in preserving marine biodiversity and ecosystem health. By adhering to best practices and investing in maintenance, verification, and training initiatives, shipowners and operators can uphold regulatory compliance, mitigate ecological risks, and contribute to the protection of our oceans for generations to come.